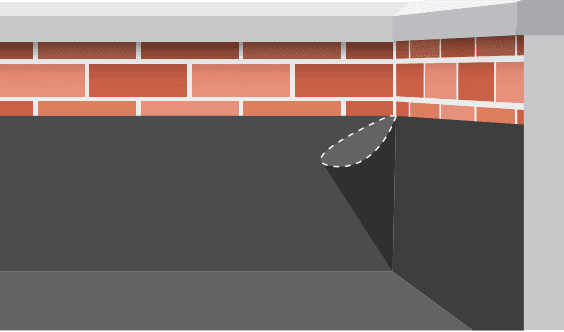

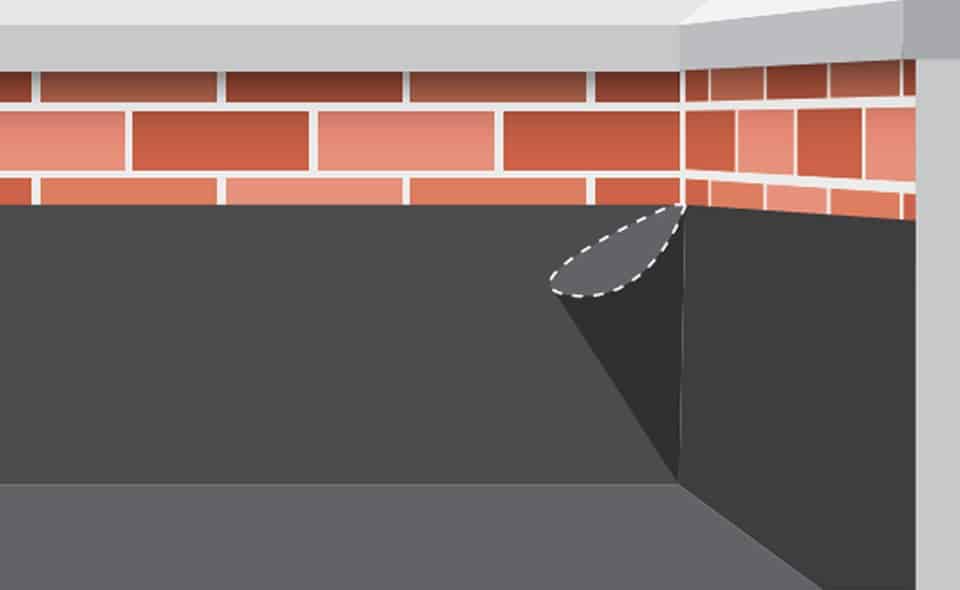

INTERNAL CORNER DETAIL

Training hub – all your questions answered!

For the best results, please follow the instructions below.

If you still have questions please feel free to contact us using the form here…

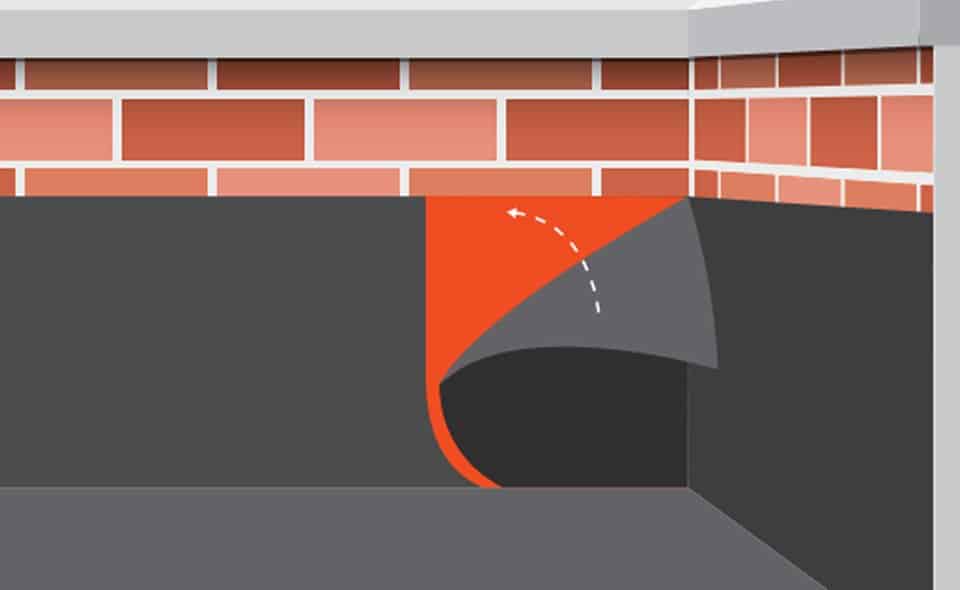

STEP 1

Form the membrane into a 45 degree (pig’s ear) shape where the membrane meets in the internal corner.

STEP 2

Cut the pig’s ear vertically 80 mm out from the flat roof corner.

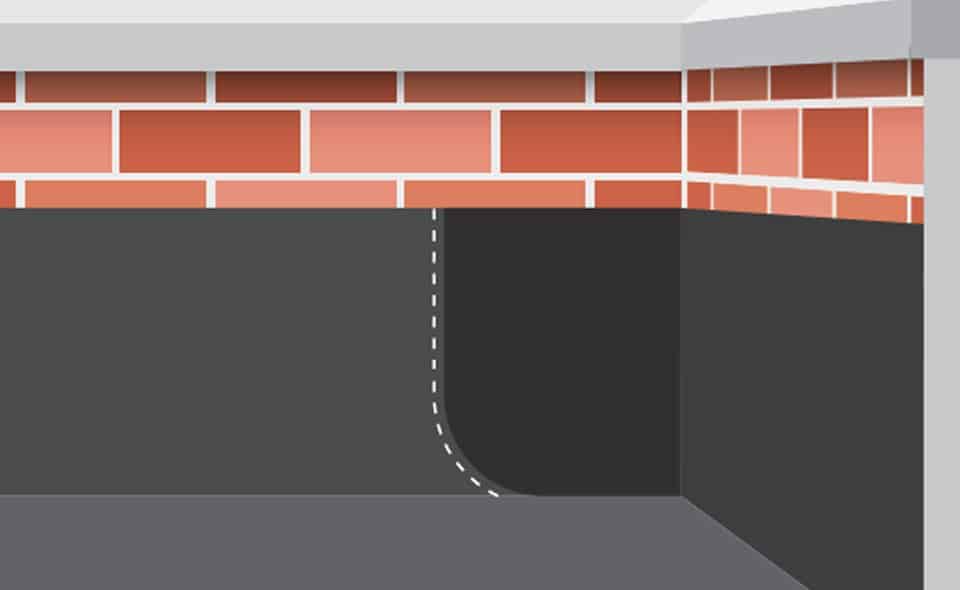

STEP 3

Cut a patch of 229 mm flashing tape 160 mm wide and offer over the pig’s ear and mark around with a scribe or pencil.

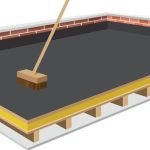

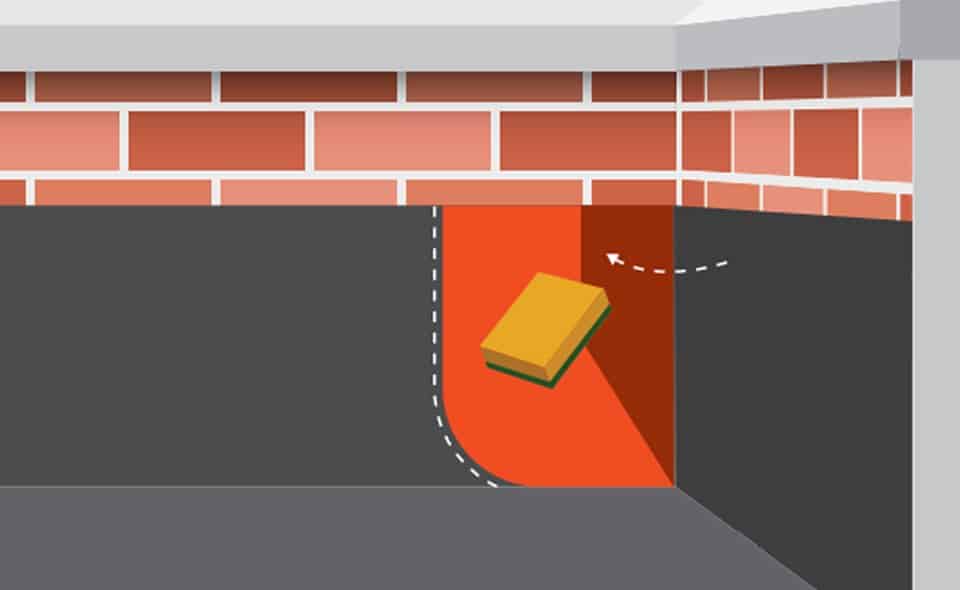

STEP 4

Firstly check primer is fully tacked off. Fold the pig’s ear back and push into the corner, then using a scrubbing pad apply a coat of primer to the other side of the pig’s ear.

STEP 5

Firstly check primer is fully tacked off. Fold the pig’s ear back and push into the corner, then using a scrubbing pad apply a coat of primer to the other side of the pig’s ear.

STEP 6

Carefully position the tape in the corner and fix from the bottom working up to prevent air bubbles forming behind the tape.

STEP 7

Once the tape is fixed in place, pressure must be applied with a seam roller to ensure correct adhesion. Please note that all FlexiProof tapes are pressure-sensitive and always require rolling.