EPDM Rubber Roofing Training Hub

Mike2024-04-09T11:21:28+01:00Flat Roof Surface Preperation

ROOF SURFACE PREPARATION The prepared roof surface must be clean, dry, and free from dust and contaminants (bitumen, oil, etc). Do not attempt to install EPDM on a damp or wet surface, as the trapped water may vaporize, causing damage to the roof sub-structure. When applying contact bonding adhesive to the roof deck in temperatures [...]

Installing the actual membrane

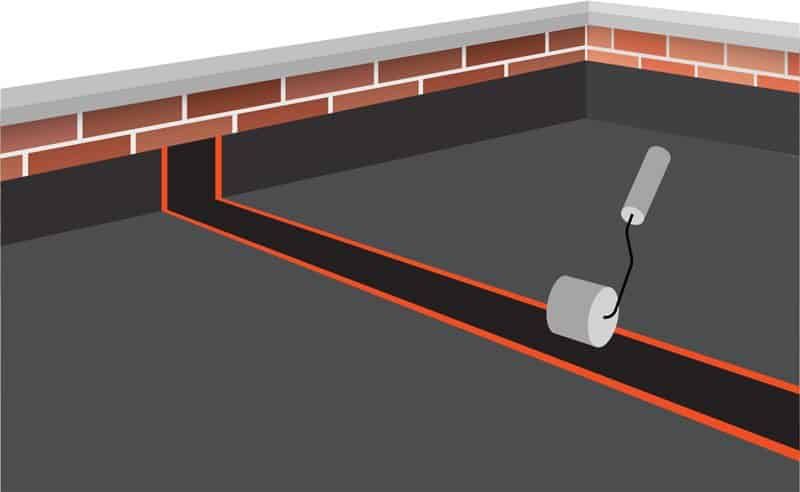

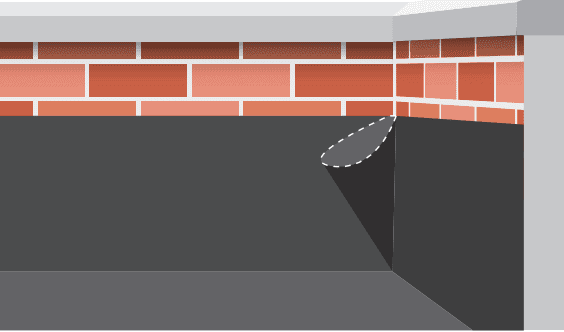

INSTALLING THE FLEXIPROOF EPDM MEMBRANE Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here… STEP 1 Unroll the FlexiProof membrane over the substrate so that the sheet is in the desired [...]

Butt joining EPDM membrane with 152mm cover strip

BUTT JOINING EPDM MEMBRANE WITH 152MM COVER STRIP Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here… STEP 1 Draw a line 90 mm each side of the membrane join with [...]

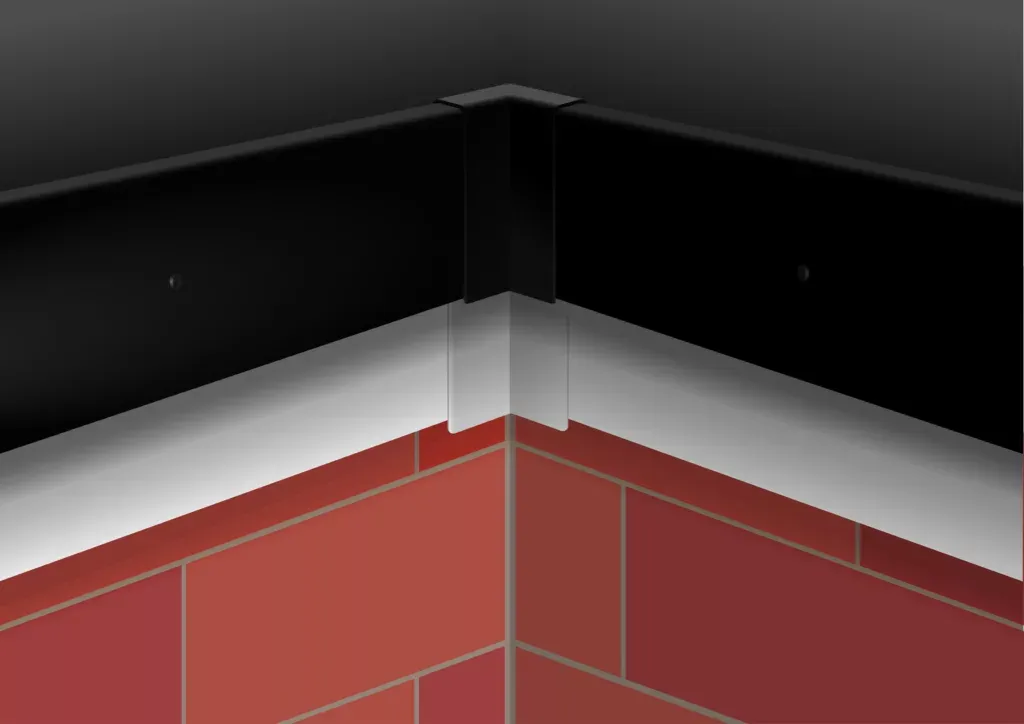

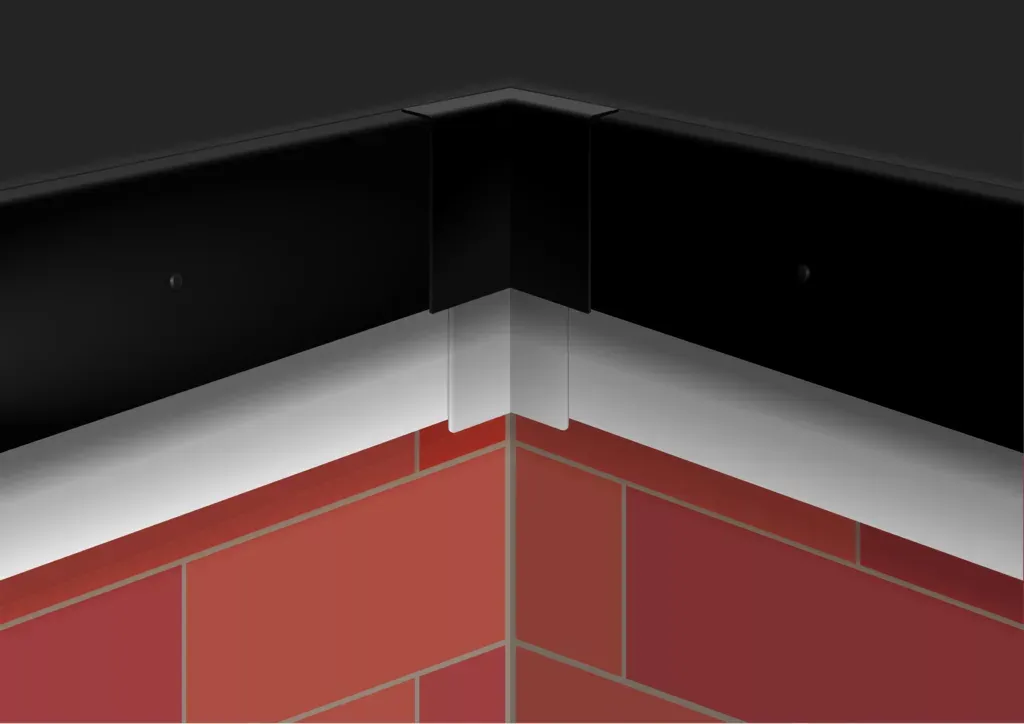

Internal Corner Detail

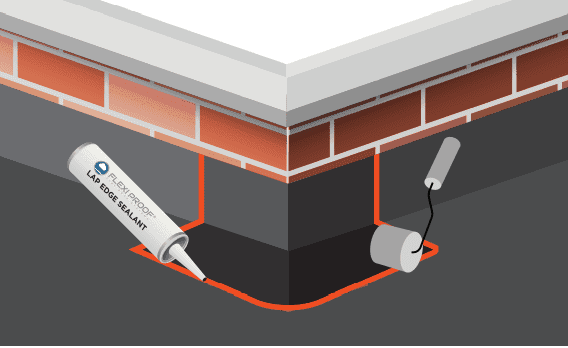

INTERNAL CORNER DETAIL Training hub - all your questions answered! For the best results, please follow the instructions below. If you still have questions please feel free to contact us using the form here… STEP 1 Form the membrane into a 45 degree (pig’s ear) shape where the membrane meets in the internal corner. STEP [...]

EXTERNAL CORNER PATCH

EXTERNAL CORNER PATCH Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions, please feel free to contact us. STEP 1 Ensure that the membrane around the external corner is clean, dry and free from dust or debris. Using a pencil, mark [...]

PIPES THROUGH THE MEMBRANE – PIPE FLASHING

PIPES THROUGH THE MEMBRANE PIPE FLASHING Training hub - all your questions answered! For the best results, please follow the instructions below. If you still have questions, please feel free to contact us. STEP 1 Pull the pipe flashing firmly over the top of the pipe. Locate the ribbed band directly above the top of [...]

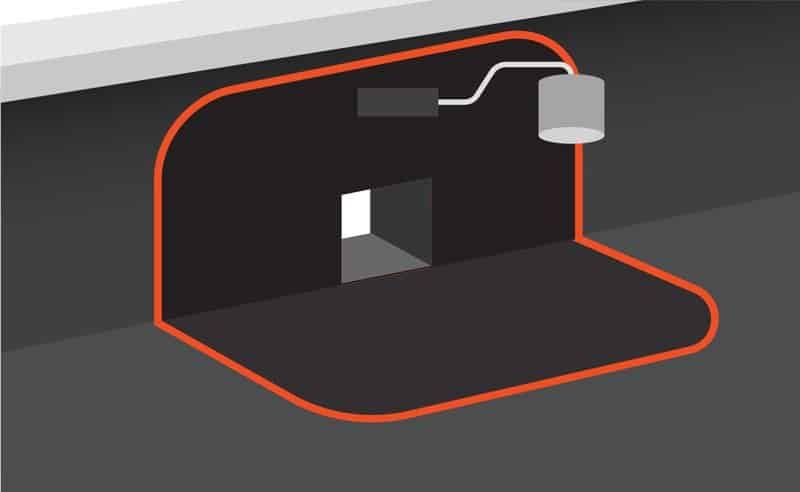

PIPES THROUGH THE MEMBRANE – PIPE BOX POCKET

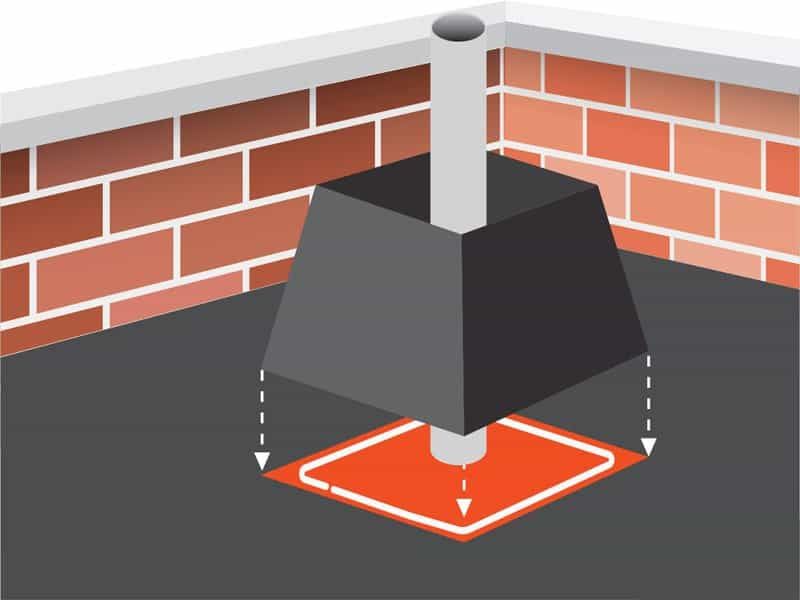

PIPES THROUGH THE MEMBRANE - PIPE BOX POCKET Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here… STEP 1 Ensure that the membrane around the pipe/penetration is clean, dry and free [...]

Installing a Wall Drain

INSTALLING A WALL DRAIN Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions, please feel free to contact us. STEP 1 Offer the wall drain into the pre-cut hole in your parapet wall and mark around using a white pencil or [...]

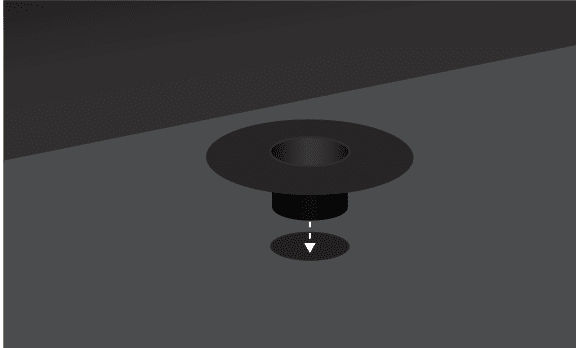

INSTALLING THE 68MM – 110MM ROOF DECK DRAINS

INSTALLING THE 68mm-110mm ROOF DECK DRAINS Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here… STEP 1 Cut down the roof drain leaving a 50 mm equal flange the whole way [...]

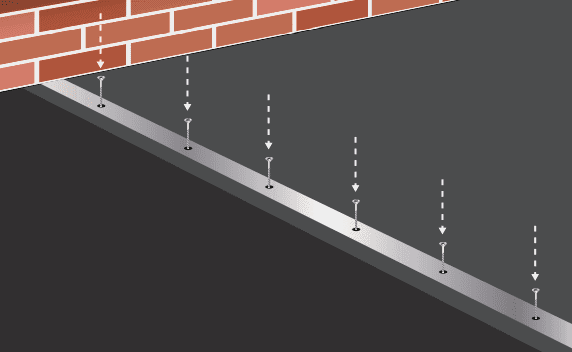

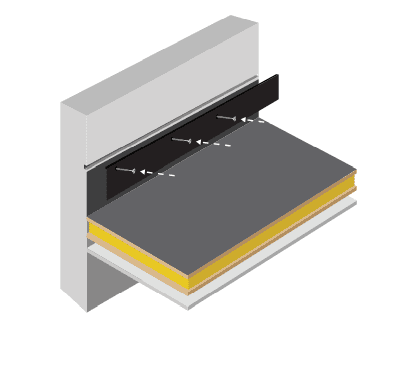

USING TERMINATION BARS TO JOIN TO OTHER ROOFS

USING TERMINATION BARS TO JOIN TO OTHER ROOFS Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here… STEP 1 Overlap the FlexiProof EPDM membrane onto the adjoining flat roof system by [...]

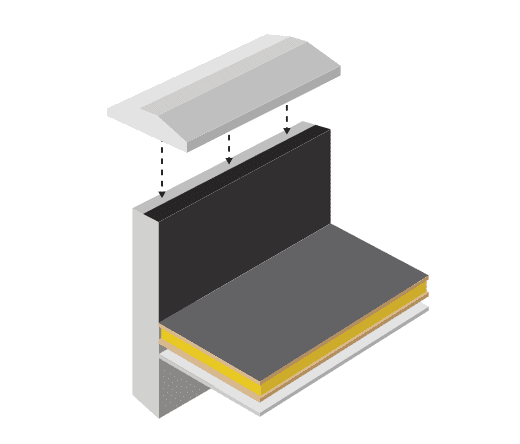

COPING STONE DETAIL

COPING STONE DETAIL Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here… STEP 1 With the coping stone removed, bond the membrane over the parapet wall leaving a 30 mm gap [...]

FITTING WALL TRIMS AND LEAD FLASHING

FITTING WALL TRIMS & LEAD FLASHING Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here… STEP 1 Before installing the EPDM membrane make sure the mortar is chased out of the [...]

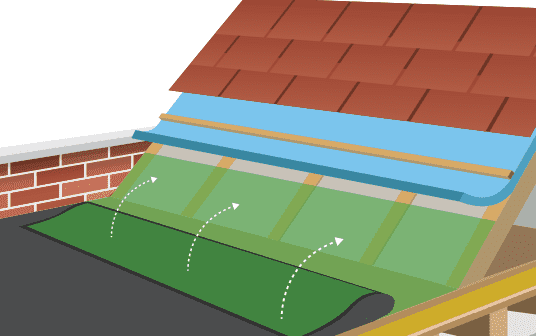

PITCHED ROOF SLOPES ONTO THE FLAT ROOF

PITCHED ROOF SLOPES ONTO THE FLAT ROOF Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here… STEP 1 Carefully strip 3 courses of tiles from the adjoining roof and remove the [...]

ROOF SURFACE PREPARATION

ROOF SURFACE PREPARATION The prepared roof surface must be clean, dry, free from dust, and contaminants (bitumen, oil etc). Do not attempt to install EPDM on a damp or wet surface as the trapped water may vaporize causing damage to the roof sub-structure. When applying banding adhesive to the roof deck in temperatures below 5 [...]

INSTALLING THE FLEXI PROOF EPDM MEMBRANE

INSTALLING THE FLEXI PROOF EPDM MEMBRANE - FLEECE-BACKED Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here… STEP 1 Unroll the FlexiProof EPDM membrane over the substrate so that the sheet [...]

BUTT JOINING EPDM MEMBRANE WITH 152MM COVER STRIP

BUTT JOINING EPDM MEMBRANE WITH 152MM COVER STRIP - FLEECE BACKED Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here… STEP 1 Draw a line 90 mm each side of the [...]

INTERNAL CORNER DETAIL

INTERNAL CORNER DETAIL - FLEECE-BACKED Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here… STEP 1 Form the membrane into a 45 degree (pig’s ear) shape where the membrane meets in [...]

EXTERNAL CORNER PATCH

EXTERNAL CORNER PATCH - FLEECE-BACKED Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here… STEP 1 Ensure that the membrane around the external corner is clean, dry and free from dust [...]

PIPES THROUGH THE MEMBRANE – PIPE FLASHING

PIPES THROUGH THE MEMBRANE - PIPE FLASHING - FLEECE-BACKED Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here… STEP 1 Pull the pipe flashing firmly over the top of the pipe. [...]

PIPES THROUGH THE MEMBRANE – PIPE BOX POCKET

PIPES THROUGH THE MEMBRANE - PIPE BOX POCKET - FLEECE-BACKED Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here… STEP 1 Ensure that the membrane around the pipe/penetration is clean, dry [...]

INSTALLING A WALL DRAIN

INSTALLING A WALL DRAIN - FLEECE-BACKED Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here… STEP 1 Offer the wall drain into the pre-cut hole in your parapet wall and mark [...]

INSTALLING THE 68MM – 110MM ROOF DECK DRAINS

INSTALLING THE 68MM-110MM ROOF DECK DRAINS - FLEECE-BACKED Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here… STEP 1 Cut down the roof drain leaving a 50 mm equal flange the [...]

USING TERMINATION BARS TO JOIN TO OTHER ROOFS

USING TERMINATION BARS TO JOIN TO OTHER ROOFS - FLEECE-BACKED Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here… STEP 1 Overlap the FlexiProof EPDM membrane onto the adjoining flat roof [...]

COPING STONE DETAIL

COPING STONE DETAIL - FLEECE-BACKED Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here… STEP 1 With the coping stone removed, bond the membrane over the parapet wall leaving a 30 [...]

FITTING WALL TRIMS AND LEAD FLASHING

FITTING WALL TRIMS & LEAD FLASHING - FLEECE-BACKED Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here… STEP 1 Before installing the EPDM membrane make sure the mortar is chased out [...]

PITCHED ROOF SLOPES ONTO THE FLAT ROOF

PITCHED ROOF SLOPES ONTO THE FLAT ROOF - FLEECE-BACKED Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here. STEP 1 Carefully strip 3 courses of tiles from the adjoining roof and [...]

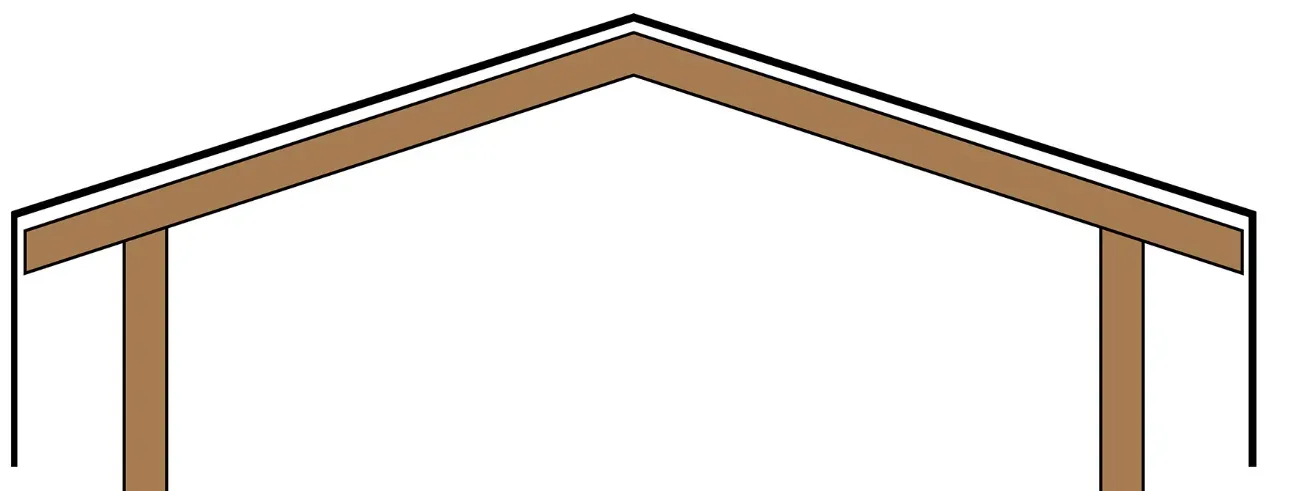

PREPARING THE ROOF

PREPARING THE ROOF - SHED RUBBER Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here… STEP 1 Open the box and familiarise yourself with the products supplied. Please also read this [...]

FIXING THE EPDM RUBBER ROOF MEMBRANE

FIXING THE EPDM RUBBER ROOF MEMBRANE - SHED RUBBER Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here… STEP 1 Fold back half of the EPDM Rubber Roof Membrane onto itself [...]

RAISED KERB TRIM

RAISED KERB TRIM - INTEGRA TRIM Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here… STEP 1 Before installing Raised Kerb Trim, make sure the fascia board is solid and high [...]

GUTTER DRIP TRIM

GUTTER DRIP TRIM - INTEGRA TRIM Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here… STEP 1 Fix the correct length of timber batten (required width x 38mm height x 25mm [...]

RAISED KERB EXTERNAL CORNER

RAISED KERB EXTERNAL CORNER Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here… STEP 1 Create an effective corner (ready for Raised Kerb Trim External Corners to be fitted) by butt-joining [...]

RAISED KERB INTERNAL CORNER

RAISED KERB INTERNAL CORNER Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here… STEP 1 Create an effective corner (ready for Raised Kerb Trim Internal Corners to be fitted) by butt-joining [...]

GUTTER DRIP EXTERNAL CORNER

GUTTER DRIP EXTERNAL CORNER Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here… STEP 1 Create an effective corner (ready for Gutter Trim External Corners to be fitted) by butt-joining two [...]

GUTTER DRIP INTERNAL CORNER

GUTTER DRIP INTERNAL CORNER Training hub - all your questions answered! For the best results, please follow the instructions as detailed below. If you still have questions please feel free to contact us using the form here… STEP 1 Create an effective corner (ready for Gutter Trim Internal Corners to be fitted) by butt-joining two [...]