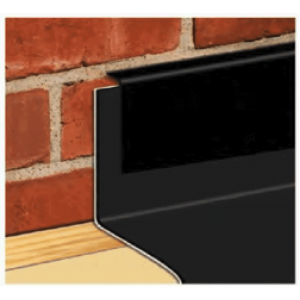

EPDM Rubber Roofing Supplies for All Flat Roof Solutions

When it comes to rubber roofing systems, we have a proven track record since 2014, giving you peace of mind that our experience ensures roofing products you can trust.

With a wide range of EPDM Rubber Roofing Supplies in stock and ready for same-day dispatch, our extensive range ensures you have everything you need for flat roof success.

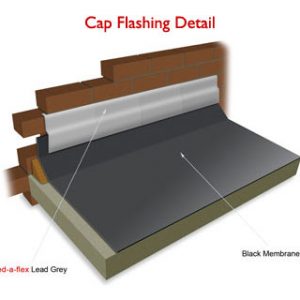

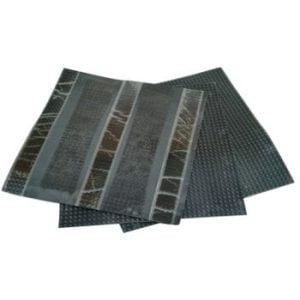

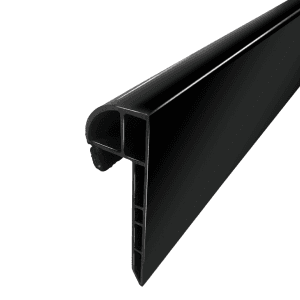

From drain outlets and seam tapes to external corners and rubber roofing membranes, we have it all.

Why not take the hassle out of the ordering process and purchase one of our all-in-one EPDM Rubber Roofing Kits? They provide everything you need in one box to weatherproof your flat roof.

If you have any questions or need help contact our customer service team for expert advice, Monday - Friday on 01306 776626 or via email.