Help & Training – The Growing Use Of EPDM Membranes

The Growing Use of EPDM Rubber Roofing Membranes in Residential Flat and Low Slope Roofing Constructions in the UK

Rubber roofing membranes are increasingly popular in the refurbishment and new construction sector due to their durability, ease of installation and practicality from a flat roofing perspective. There are several reasons which are driving the popularity of this type of flat roofing system, including;

Cost – EPDM is an extremely affordable solution over traditional bitumen flat roofing systems, with the standard 1.2mm thick sheet being very similar in price to bitumen roofing felt. Further variants of the EPDM sheeting,, such as the 1.5mm thick commercial grade EPDM and fleece re-inforced EPDM,, work out at approximately one-third More in material costs than bitumen roofing felt. However, as the membrane is installed in one thickness (single ply), labour costs over traditional methods are decreased by two-thirds.

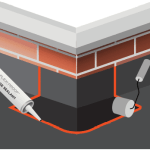

Ease of installation—EPDM is very straightforward to install, requiring a small number of tools. Competent DIY experts can fit it on straightforward installations; a competent Roofing Contractor should complete more advanced works.

Life Expectancy – rubber membranes have a Proven 50-year Life Expectancy.

Alternatives to EPDM

Single Ply sheeting such as the uPVC (Poly Vinyl Chloride)and TPO (thermoplastic olefin) are sometimes used in the Residential sector but normally become cost-prohibitive due to a labour-intensive installation, which requires all seams to be heat welded.

Recently, the NFRC (National Federation of Roofing Contractors) prohibited all members from using naked flames to torch Polymer bitumen felts onto combustible roof decks. This has created a difficult situation as an urgent requirement has arisen to source an alternative, cold method to install flat roofing systems, further increasing the use of membrane and liquid-applied systems. Felt Systems with special base sheets are now available to allow a roofing torch to be used on the top side of the base sheet, although these are very expensive.

History

Carlisle, an American company, was among the first to manufacture EPDM as a flat roofing membrane. Production started in the 1960s, and the membrane blends have remained virtually unchanged. Furthermore, some of the first rubber roofs installed are still watertight, demonstrating their durability and cost effectiveness.

Whilst the original EPDM roofing systems are able to provide the strength that you need for a flat roof, the manufacturers are still committed to developing new types of rubber membranes to further advance its capability to withstand weathering and general wear and tear. In addition to this, further technological advances are sought to streamline the installation process and reduce the number of tools used to apply the membrane to the deck.

In the 1980s, seam tapes joined the membrane sheets together to replace the existing seam adhesives. This reduced installation times and improved the reliability of on-site seaming. It wasn’t until the early 2000s that pre-applied seam tapes (PST) were used further reducing the amount of time to complete seaming works by up to two thirds which resulted in the membrane being one of the fastest single ply roofing systems available on the market to install.

EPDM system guarantees vary, but many installations include a 20-year warranty.

The history of the EPDM membrane has certainly changed and continuing advances in technologies mean that more and more improvements are being made to the membrane and the techniques required to install the system. This ultimately saves money for the customer and reduces the amount of labour required from the installer. Buying a similar system produced by Carlisle Syntec and sold in the UK under the brand names “ClassicBond” or “Duoply” ensures you’re purchasing a roofing system with the longest proven track record in the market.